Dispense air-free, accurately metered, mixed and dispensed epoxies and urethanes into APT vacuum chambers for superior penetration and void-free vacuum cast parts.

Vacuum-potted components ranging in size from automotive ignition coils to large MRI body- imaging coils often require air-bubble and void-free penetration of the mixed epoxy—around every turn of wire and under hard-to-reach overhanging ledges.

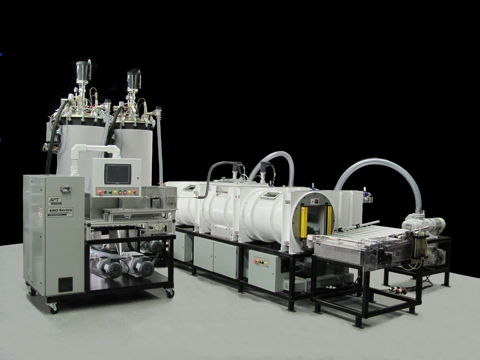

When connected to one of our ECS-Series or HT-Series metering, mixing and dispensing machines, our complete vacuum potting and encapsulating systems are equipped to precisely control your formulation’s ratio, shot-size and output rate — to deliver air-free material into your molds at precisely preset and controlled vacuum levels. The resin degassing tanks connected to the dispensing machine can be equipped for either batch or continuous thin- film resin degassing.

Typically, digitally-controlled vacuum at better than 0.5 mmHg is continuously drawn on the resin materials in the supply tanks, while high-voltage components to be potted inside the vacuum chamber are also digitally maintained at a precise vacuum level to insure bubble-free casting of on-ratio, abrasive-filled mixed material, into those mold cavities. High-voltage electrical and electronic components demand vacuum potting, however other critical air-free applications, including vacuum-assisted RTM, utilize vacuum casting to produce void-free parts.

APT’s metering and mixing systems feed air-free mixed material to both standard and custom- built vacuum chambers to produce the highest quality, void-free parts. What size or type of chamber is right for your application? Our people can work with you to select one of our existing manual or automatic chambers or we can design one that meets your specific application requirements.

Your vacuum chamber can be as simple as a small chamber with a front-opening door. On the other hand, for high volume output, if you need to minimize the time spent cycling from vacuum to vent, our continuous flow-through vacuum chamber includes three chambers and four automatic doors. This system allows the center chamber to be maintained under constant vacuum (i.e., no vacuum/vent cycles) to maximize pour time inside the center chamber. These systems include automatic valves for connection to the vacuum pump and for venting vacuum to ambient pressure.