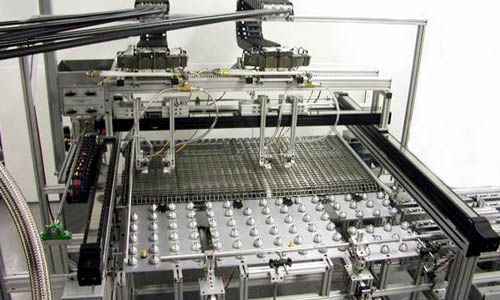

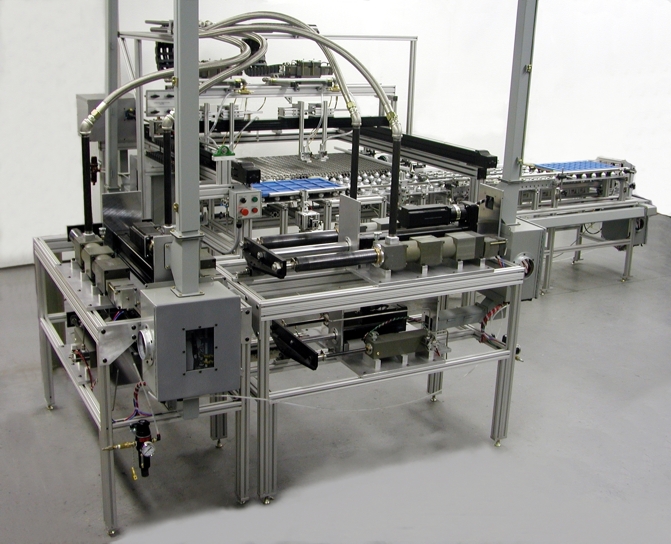

ECS-Series systems are specifically designed to degas, meter, mix and dispense abrasive-filled and unfilled, multiple-component reactive resin formulations. They handle epoxy, cast urethane, nylon and polyester materials. Typical applications include open casting, open potting and encapsulating, encapsulation of high-voltage ignition coils inside vacuum chambers, RTM (and/or VARTM) resin injection of advanced composite parts. Plus, these ECS machines are available with full automation, including coveyorized systems with mold identification, transfer conveyors and servo-driven X-Y-Z Axis (multiple) pour nozzle positioning.

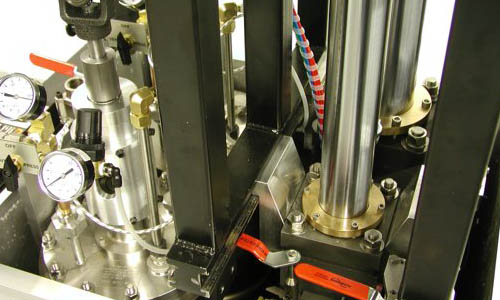

Extremely accurate and fully programmable, ECS-Series Piston Pump Systems include state-of-the-art PLCs, accurate temperature control from room-temperature to 500oF, digital servomotor-control and Coriolis mass flowmeters for closed loop-feedback ratio and flow control.